Why Power Efficiency Is Critical in 2026

IoT devices are being pushed farther into the field literally. From remote agriculture sensors to wildlife trackers and off grid infrastructure monitors, edge deployments are becoming the norm. These devices often run on battery for months or years, without easy access to mains power or human intervention. That means power consumption isn’t a side concern it’s the whole ballgame.

At the same time, sustainability isn’t just a buzzword anymore. Environmental regulations and consumer expectations are driving tighter constraints on energy usage and material choice. Mass deployment of inefficient devices isn’t just costly it’s a reputational risk. Designers are now prioritizing energy footprints as a core design goal, not an afterthought.

Built right, power efficient IoT extends battery life, reduces maintenance costs, and keeps the planet (and your bottom line) healthier. It’s no longer about just making the tech work. It’s about making it work smart for the long haul.

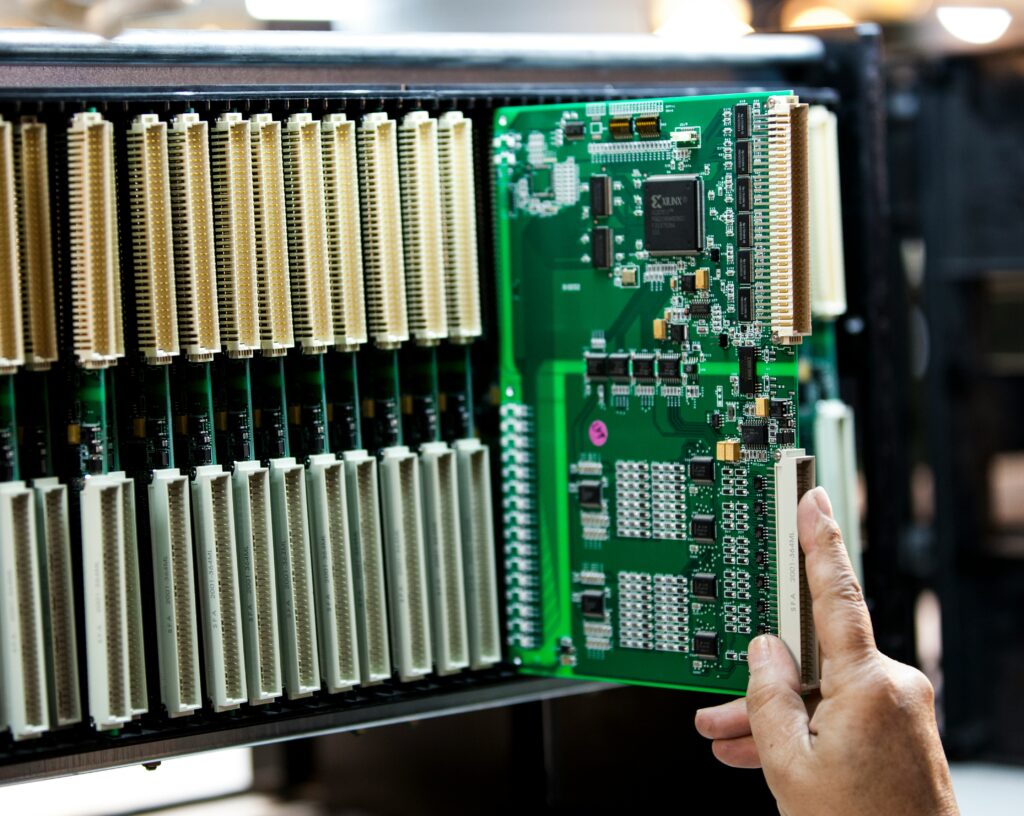

Hardware Level Power Optimization

Reducing power consumption in IoT starts with the hardware you choose. That means selecting microcontrollers (MCUs) and sensor modules built for ultra low power operation. These aren’t just buzzwords sub microamp sleep currents and aggressive clock gating can stretch battery life from months to years.

But even the best silicon won’t save the day by itself. Energy harvesting is seeing real traction, especially in remote deployments where replacing a battery isn’t practical or worth the cost. Solar’s the obvious go to, but thermal gradients and ambient radio frequency (RF) energy are starting to pull their weight too. When paired with smart storage and power management ICs, these methods can keep a node alive almost indefinitely.

Communication also matters sometimes more than people think. Protocols like LoRa and Zigbee are built for low duty cycle, long range data transmission. BLE 5.2 adds modern connectivity with less draw. Picking the right one isn’t just about range or data rate it’s about matching how often and how far your device needs to talk.

Finally, component level sleep modes are non negotiable. Your sensors, radios, and MCUs should disappear into deep sleep when idle. Wake times, debounce timing, and wake sources all need tuning. This isn’t luxury optimization it’s what separates hobby prototypes from scalable deployments.

Smart Firmware Strategies

Reducing power consumption on the firmware level starts with a hard look at how much time your device spends awake and for what purpose. Every millisecond of processing adds up. Aim for minimal active time by stripping out redundant loops, avoiding prolonged computations, and making every instruction count. Tight, purpose driven code is your friend.

Interrupt driven logic beats polling every time. Polling ties up the CPU, chewing power while it waits. Interrupts, on the other hand, let your system sleep until something important happens like a sensor reading crossing a threshold. It’s a cleaner, leaner way to operate if you care about battery life (and you should).

You can go one step further by making transmission intervals smart. Don’t fire off data at fixed intervals because it’s easy. Base your transmissions on actual changes in the environment when a sensor detects something notable, then trigger an update. This cuts down on noise and helps avoid wasting energy on business as usual.

If your device handles multiple tasks, consider embedding a real time operating system (RTOS). It can intelligently schedule tasks to reduce idle overhead and prevent one process from hogging the system. With a lightweight RTOS, you get orderly execution and power aware scheduling without bloating the firmware.

For more hands on help refining your firmware performance, check out How to Improve Device Boot Times with Firmware Tuning.

Efficient Data Communication

When it comes to squeezing every drop of battery life out of an IoT device, your data strategy matters a lot. Sending data is one of the most power hungry operations, so reducing data load is step one. Strip out the fluff. Send only what’s essential, and do it infrequently.

Edge processing plays a big role here. Instead of streaming raw sensor data nonstop, process and summarize it locally. Use logic at the device level to decide what’s worth transmitting. If the temperature hasn’t changed in two hours, for example, why burn battery talking about it?

Batching transmissions is another smart move. Instead of pushing every minor update immediately, queue up data and send it in one burst. This reduces radio wake ups and keeps your device in low power modes more often a win for duty cycling.

Finally, apply compression wherever it makes sense. If your data payloads are repetitive or large, formats like CBOR or lightweight JSON alternatives can shrink it down without losing key context. Just make sure the trade off doesn’t overload the microcontroller during compression balance is key.

In short: be deliberate. What your device says, how often it talks, and how loud it needs to shout all impact your power budget.

Power Profiles and Sleep Management

If you want to cut power use in any serious IoT deployment, start by measuring it. Tools like a Joulescope or a high resolution shunt resistor setup give you a real picture not just estimates of when and where the energy is going. Once you’ve got your baseline, you can tune accordingly.

Most MCUs support several power modes: active, idle, and standby (sometimes called stop or deep sleep). The idea is simple run wide open when needed, then drop to the lightest mode possible when you’re done. Active mode for crunching numbers. Idle for waiting on a timer. Standby when you’re not doing anything at all. The trick is knowing when to switch and setting up your code to respond efficiently.

Don’t ignore the peripherals. A sensor that takes 100ms to warm up can blow up your power budget if it’s triggered too often. Managing wake up times and debounce routines especially for mechanical switches is low hanging fruit. Timing matters here. Batch peripheral access when you can, and choose components with fast startup times.

Dynamic frequency scaling is another tool in the kit. If your task is light, drop the CPU clock speed. Processing at full throttle is wasteful if you don’t need the horsepower. Many modern MCUs let you scale both clock and voltage. Match performance to demand and you save energy without hurting functionality.

It’s not sexy work. But squeezing out every microwatt is how long life, low maintenance devices are built.

Remote Power Diagnostics & Updates

Remote capabilities are no longer optional they’re a baseline, especially in battery powered or hard to reach IoT deployments. Over the air (OTA) firmware updates have matured, allowing for more intelligent, sleep aware scheduling that doesn’t wake up devices unnecessarily. Updates can now be staggered, incremental, and embedded into existing wake cycles to avoid draining power just to patch code.

More teams are also leaning into remote power monitoring. Collecting continuous telemetry on current draw, sleep duration, and active vs. idle time gives firmware engineers the data they need to optimize behavior in the field, not just on the bench. It’s not glamorous, but it’s where massive efficiency gains live.

Fail safe routines are another critical piece. Power spikes during bootloops or failed firmware deployments are a silent killer. A resilient fallback path a known good firmware image, a soft limit on retries, low power safe mode prevents devices from thrashing through battery life when something goes wrong. Don’t assume ideal conditions. Build features with failure in mind.

Final Tips for Design Optimization

Power optimization isn’t a final polish it’s something you bake in from the start. Decisions made early in the product lifecycle have ripple effects. A last minute fix to reduce power draw won’t undo months of inefficient system design. So bring power constraints into the conversation right from planning and prototyping.

Your hardware, firmware, and software teams can’t work in silos. Efficient systems come from deliberate coordination across disciplines. That might mean aligning sensor sampling with radio transmit schedules, or structuring firmware to accommodate future updates without bloating idle power usage. This kind of synergy doesn’t happen by accident it needs to be built into the process.

Testing also needs to step out of the lab. Simulated use cases don’t cut it anymore. Battery life depends on messy, real world conditions: thermal drift, signal congestion, user behavior. If your device sleeps beautifully in a test rig but constantly wakes due to noisy sensors in the field, you’ve missed the mark.

Lastly, design for change. Your firmware will evolve. Sensors may swap out. A cloud provider may tweak its API cadence. Systems that can’t adapt without doubling their power budget are fragile. The more maintainable your architecture, the better chance you have at staying efficient in the long run.